The production and processing of asphalt can get very dirty. The bitumen obtained from petroleum, which serves as a binding agent between various aggregates in the asphalt, is not water-soluble and can cause considerable contamination on surfaces that come into contact with the sticky mass.

Because machines and devices contaminated with bitumen are very difficult to clean, they should be pre-treated before they are used. This is where asphalt release agents come into play, which protect the surfaces from contamination in order to ensure the longevity of the equipment that is used in asphalt production and road construction.

Requirements for asphalt release agents

- Good separating effect between bitumen/asphalt and machine surfaces

- Reduction of the cleaning effort to a minimum

- Good adhesion to vertical surfaces

- Universally applicable with different asphalt mixtures

- No negative effect on the asphalt properties

- Corrosion protection of machine and vehicle surfaces

- Harmless for the user and the environment

Use of asphalt release agents

Even today, diesel is occasionally used as a release agent in practice. However, this affects the structural integrity of the applied asphalt in the pavement. In addition, diesel poses a serious threat to the environment. Modern asphalt release agents are not only environmentally friendly - they are also harmless to users and when using various types of asphalt, such as B. mastic asphalt or stone mastic.

Typical areas of application

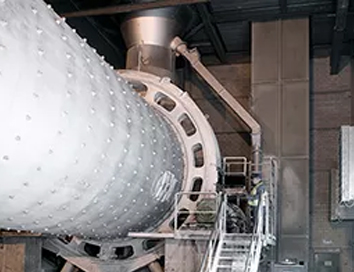

- Asphalt mixers / asphalt mixing plants

- Truck beds

- Feeder belts

- Asphalt pavers

- Pneumatic rollers and tandem rollers with steel surfaces

- Other devices and tools that come into contact with hot asphalt

How should asphalt release agents be used?

Before applying the asphalt release agents, the surfaces to be treated must be completely clean. When applying with a spray device, make sure that an oil-resistant hose is used and that the pressure is between 4 and 6 bar. A flat jet nozzle made of stainless steel is recommended. The release agent can also be applied thinly and evenly with a brush.