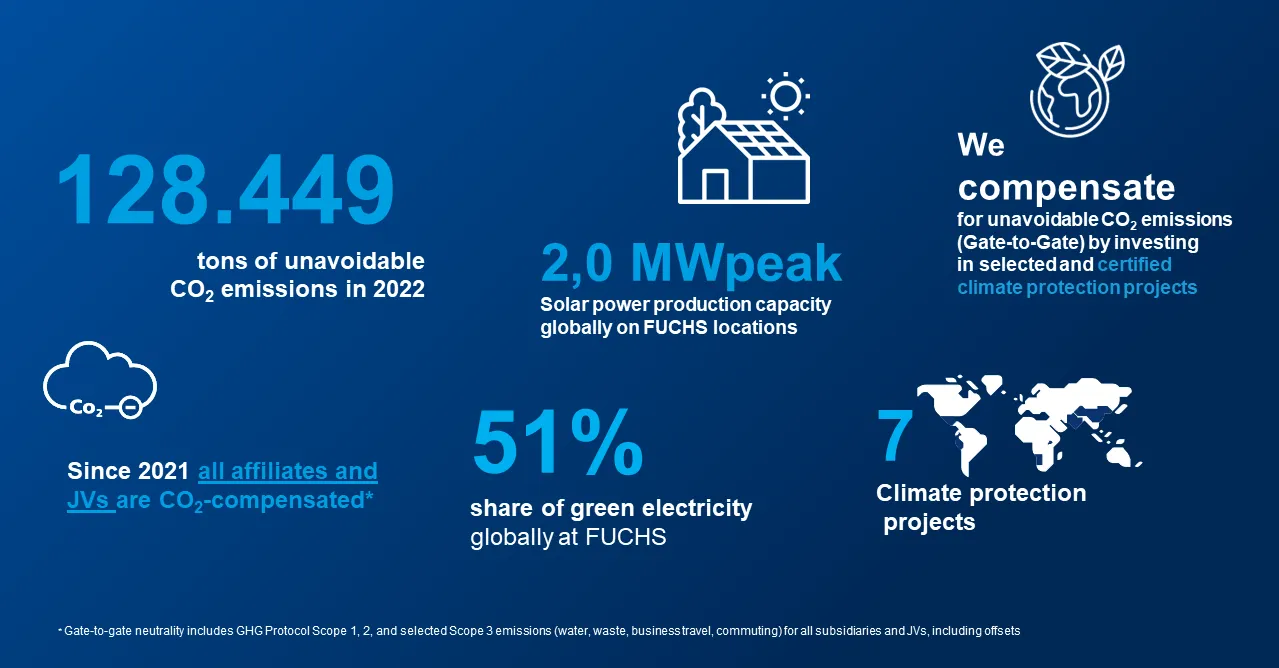

A genuine milestone in FUCHS' company history: Since 2020, FUCHS has been completely CO2-compensated at all of its more than 60 locations worldwide – from the energy consumption in production all the way up to the consumables used in administration operations. Yet we do not just focus on the ecological footprint in our own factories, but look beyond ourselves to the entire process and value chain of our products. This is why we participate in research projects on the use of sustainable raw materials. Together with our suppliers, we develop standards and measures for quantifying and certifying sustainability along the entire value chain. Above all though, our products reduce friction and increase energy efficiency for our customers – this has both a financial and ecological impact.

The path to 2040

Active player for sustainability

Sing World Group carbon-neutrality strategy is embedded in our sustainability strategy, which began in 2010 when we signed the "Code of Responsible Conduct for Business". In 2018 we joined the "Alliance for Development and Climate" led by the Federal Ministry for Economic Cooperation and Development. At the same time, we initiated the foundation of a sustainability workgroup under the umbrella of the Union of the European Lubricants Industry (UEIL). Together, we develop harmonized sustainability standards, KPIs, and benchmarks to enable sustainability-based comparisons

Product Carbon Footprint

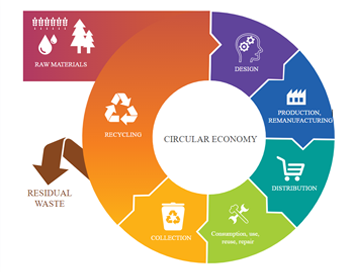

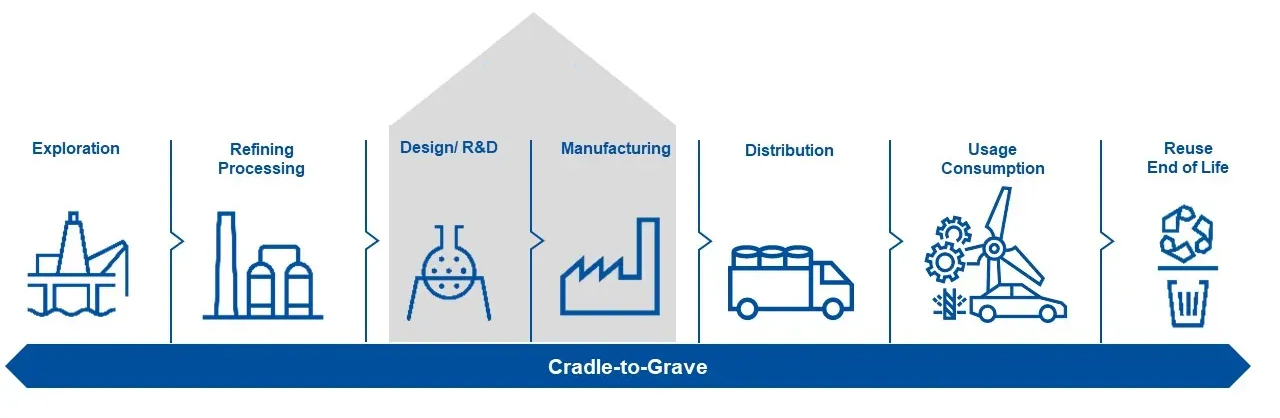

With the EU climate targets, more and more companies are focusing on their own emissions and a possible climate neutrality of business operations. The calculation of the product carbon footprint (PCF) is a major factor in this context as it summarizes all emissions along the value chain which are related to the product.

Greenhouse Gas Emission Reduction Targets and Action Plans

The main objective for our Science-based Greenhouse Gas Emission Reduction Targets is to limit global warming to 1.5°C. To achieve this this, we set two reduction targets as required by SBTI-framework: Our Mid-Term Goal aims for 2030 and to reduce Scope 1 & 2 emissions by at least 42% and Scope 3 by minimum 25%. Our Long-Term-Goal has been set for 2040 and this is to reduce all emissions (Scope 1, 2 & 3) by at least 90%. The base year for these reduction goals is 2021.

Our strongest driver to reduce scope 1&2 emissions is to procure all energy required globally from renewable sources or to self-generate the required electricity on-site. However, in the base year 2021 Scope 1 and 2-emissions accounted only for roughly 4% of our total emissions as SING WORLD GROUP is not considered to be an energy intensive operation. The majority of Scope 3 emissions stems from category 3.1 “Purchased Goods and Services”. Therefore, in order to achieve the Scope 3 reduction targets the following action plan has been set (excerpt)

1. Replace virgin base oil with bio based base oil.

2. Replace virgin mineral base oil with recycled base oil.

3. Purchase low PCF alternatives if available.

Raw materials

Buying sustainably

We know that conducting carbon-neutral operations within our own company alone is not enough. Our goal therefore is to sell carbon-neutral products long-term – and we get our suppliers on board to do this by purchasing raw materials. After all, these are responsible for 90 percent of the carbon footprint of a finished lubricant product. Within the scope of numerous research projects, we already support some of our suppliers in the search for corresponding options. And we've brought them all to the table: suppliers, competitors, and customers, in our European industry association UEIL. The objective here is to achieve measurable key performance indicators and criteria for sustainability.

Focus on biogenic raw materials

The use of biogenic raw materials from Europe as renewable, environmentally friendly alternatives to fossil raw materials is at the center of many of the research initiatives in which SING WORLD GROUP is involved. Their main benefit is that they do not increase the carbon balance and their use often means a new source of income for domestic agriculture.

From deep-fat grease to a new raw material for high-performance specialty lubricants

Huge amounts of waste grease are produced every day in industry and in everyday life. Especially in restaurants and snack bars, carbon-rich residual streams such as used frying fat are produced in large quantities, the potential of which has hardly been unlocked to date.

That is why SING WORLD GROUP is actively taking part in research. And together with our research partners, we were able to refine frying fat to produce new, high-quality raw materials for lubricants.

Strategy to promote the use of alternative raw materials

In 2023, we defined our Global Procurement Strategy that identifies the key areas of improvement to be developed and achieved to fulfill our set emission reduction targets. This strategy is informed by the SBTi (Science-based Targets Initiative) to help to quantify the measures taken in the coming years. In the mid to long term, we strive to significantly increase the usage of circular products in raw materials and packaging as well as biogenic based raw materials. In close co-operation with our suppliers, we are starting to develop a path forward with them to achieve -25% carbon emission by 2030. This is a multi-step process and will potentially imply the use of new raw materials that require many R&D activities to deliver the technology and performance requested by our customers.

Each procurement category must define in the course of 2023 and latest 2024 their contribution to SING WORLD GROUP GROUP’s sustainable targets.

Moreover, in 2023, SING WORLD GROUP again requested information from its top raw material suppliers on the Product Carbon Footprint values for the raw materials purchased in the EMEA region. This request will be repeated regularly in the future and include additional regions and suppliers. This will help to increase transparency throughout our value chain and to prioritize the projects to be implemented to reduce SING WORLD GROUP’ Carbon Footprint. Suppliers were also informed that this criterion will be increasingly taken into consideration to reward new business and contract at SING WORLD GROUP.

Producing and using energy responsibly

Naturally, the first thing we look at in terms of sustainability at all of our sites worldwide is our own production, as this is where we can make direct changes. In this way, we have succeeded in lowering CO2 emissions per produced ton of lubricant by 30 percent since 2010. And through continuously optimizing procedures and processes, we will further reduce energy and water consumption and further increase the share of green electricity which reached 51% in 2022. In this way, we will be able to gradually roll back carbon-compensation measures through the support of climate protection projects in the medium term.

Best practices from the Sing World Group

Germany: Production site heats test bay

A perfect example of ecological responsibility at the Mannheim site: High-temperature condensate from the neighboring production site is used for the newly built test field building and to keep an adjacent warehouse frost free. The high-temperature condensate supplies both the ventilation systems as well as the heaters and ceilings of the test bay building via heat exchangers. The environmentally friendly result: 18 tons of carbon dioxide are saved each year.

Great Britain: 2,000 solar collectors

The British FUCHS subsidiary is setting a good example. Around 2,000 solar collectors on the roof of the new office at the company headquarters in Hanley, Stoke-on-Trent, produce around 14 percent of the energy required for the entire site. 95 percent of the lighting is supplied by LED lights – and in the new, fully automated warehouse with 4,000 pallet spaces a rainwater system collecting 1.8 million liters of water per year has been installed in 2020.

Spain: 335 kilowatt peak solar panels

Another excellent project that brings us closer to our goal of being more sustainable is at the subsidiary in Spain. FUCHS operates numerous plants and warehouses around the globe with a lot of roof space. While others invest in setting up their own wind parks, FUCHS can use the surfaces it has for building solar systems. That's exactly what is currently happening at the Spanish site in Castellbisbal. An installation covering 1,650 square meters with an installed power of 335 kilowatt peak is being built on the roofs of several warehouses.

Support for climate protection projects

Not all emissions can currently be completely avoided – we compensate these remaining emissions through our involvement in selected climate protection projects in regions where we have our own sites. Our focus here is on expanding renewable energies. The projects must hold internationally recognized certification such as the Gold Standard. Its criteria are developed by organizations like the WWF.

Climate protection projects 2023

Forest protection in Brazil: The project preserves the rainforest. The aim is, that the “Ribeirinhos”, the inhabitants of the Amazon acquire officially the relevant property rights. This ensures that the area is no longer classified as unused and can thus be legally occupied for deforestation At the same time, it secures the livelihood of the local population, which is one of the poorest in all of Brazil. A reduction of 364.244t CO2e can be achieved annually as a result

Reforestation in China: The project includes improved forest management of a total area of 7,746.7 ha. The trees of this forest area were converted into protected forests. The tree species are mainly fir and pine. The amount of emissions saved is approximately abut 86,680t of CO2e per year. The project activity contributes to the protection of the environment and biodiversity, thus contributing to sustainable development.

Hydropower in India: The hydroelectric project is a 4 x 100 MW run-of-river power plant and generates electricity from hydro-power with focus on renewable energy. The average annual emission reductions of the project are approx. 1,468,106t CO2e, reducing the anthropogenic greenhouse gas emissions that would have generated if fossil fuel electricity had been fed into the grid.

Hydropower in Indonesia: As well as providing clean energy, the project reduces GHG emissions by displacing fossil-fuel derived energy that currently provides 313.500 MWh each year to Sumatra’s grid. 270.000t of CO2e are reduced each year. The local population of this remote region benefits from more employment opportunities that also include technical trainings.

Wind power from Turkey: The project involves the installment of 20 wind turbines, each with a capacity of 3MW. In a second project step, another 10 turbines with a capacity of 3.3 MW each will be added. The project will thus generate around 287,000 MWh of clean wind power per year, which will be fed into the regional grid.

Hydropower in Turkey: The hydropower project involves the construction of a new 93 MW run-offriver hydropower plant. The main objective of the project is to generate about 335 GWh p.a. of electricity to supply the national grid using a renewable resource and tapping the significant hydropower potential in the region. The emissions saved amounts to 187.471t CO2e p.a.

Musi Hydro Power Plant in Indonesia: The project located on Musi river/basin in Bengkulu, Indonesia is a new run-of-river type hydro power plant. Total installed capacity of Musi is 210 MW, consisting of three 70 MW turbines. The project supplies electricity to the connected Sumatra grid. The electricity currently generated by the grid is relatively carbon intensive. The project will increase the utilization of renewable energy sources, here hydro energy, by operating a new hydropower plant