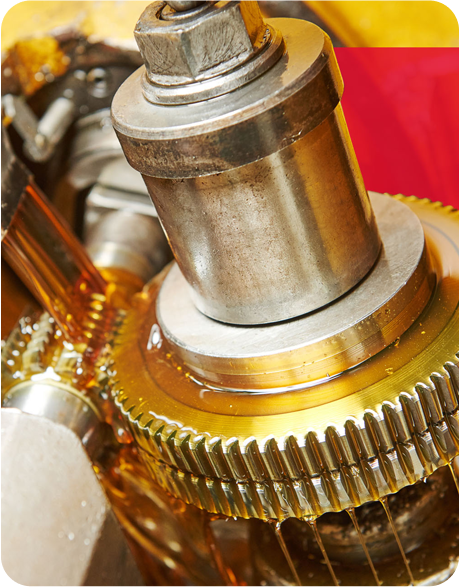

Reduced friction for extended machine life

When it comes to machinery, friction and premature wear are major concerns that can lead to costly breakdowns and decreased productivity. The application of good lubricants effectively mitigates these risks. By reducing friction between moving parts, lubricants act as a protective barrier, preventing direct metal-to-metal contact and minimizing wear. As a result, machinery experiences less strain, operates smoothly, and enjoys an extended lifespan.

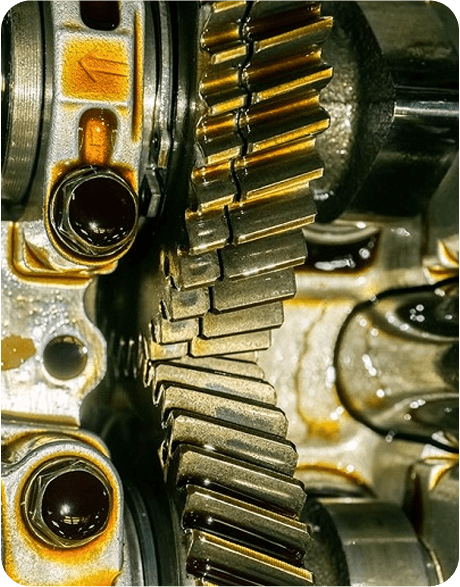

Minimized maintenance and enhanced productivity

Using high-quality lubricants is an investment that pays off by significantly reducing maintenance requirements. Regular lubrication with the right products ensures that machinery remains in optimal condition, with less frequent repairs and component replacements necessary. This reduction in maintenance translates into cost savings, increased uptime, and enhanced productivity.

Improved energy efficiency

In addition to extending the life of your machinery, the use of proper lubricants improves energy efficiency. Friction is a primary source of energy loss in mechanical systems. When machinery experiences excessive friction, more energy is required to overcome it. Using high-quality lubricants that effectively reduce friction, will significantly lower energy consumption. The result: reduced energy costs and a positive environmental impact.

Sustainability: reducing CO2 emissions

Promoting sustainability is a global responsibility that affects every industry. Lubricants play a crucial role in achieving environmental goals. Studies have shown that the use of advanced lubricants can result in emission reductions of up to 10%. By choosing Interflon's lubricants, you can align your operations with sustainability objectives, effectively reducing your environmental impact while simultaneously optimizing your machinery's performance.

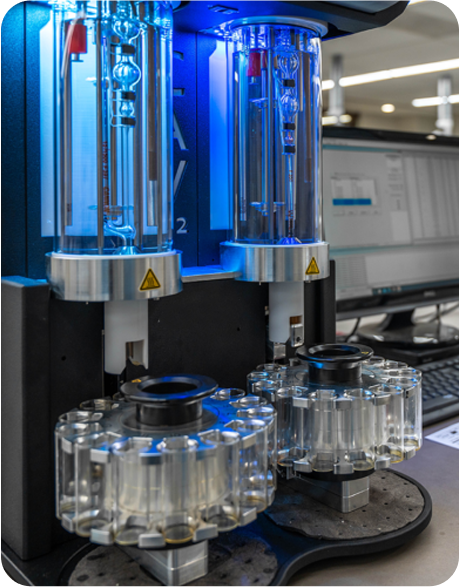

Specialized solutions for the food industry

In the food industry, ensuring the safety and compliance of lubricants is of utmost importance. Interflon recognizes these unique requirements and offers innovative food-grade lubricants that are NSF H1-certified. These lubricants meet the stringent regulations and standards set for the food industry, making them optimally suited for applications where incidental food contact may occur. By utilizing Interflon's food-grade lubricants, you can maintain the highest levels of hygiene, safety, and performance in your food processing and packaging operations.

Conclusion

In summary, the importance of good lubricants cannot be overstated. Interflon's lubricants featuring our revolutionary MicPol® technology, protect your machinery, minimize maintenance efforts, and enhance overall performance. The reduction in friction achieved through these lubricants leads to extended machine life, improved energy efficiency, and decreased CO2 emissions. Additionally, our specialized food-grade lubricants ensure the highest levels of safety and compliance in the food industry. With Interflon, you can unlock the full potential of your machinery while actively contributing to a more sustainable future.