What is industrial paint?

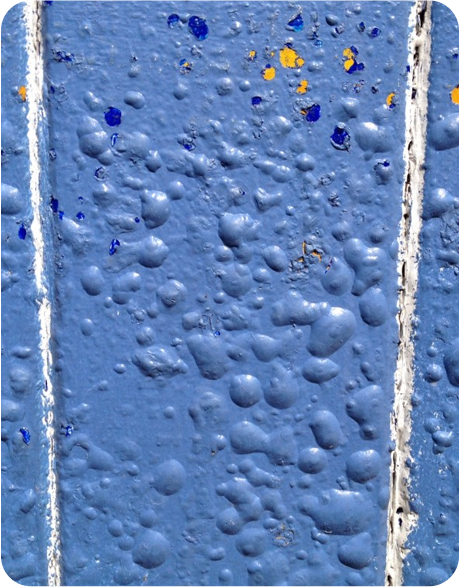

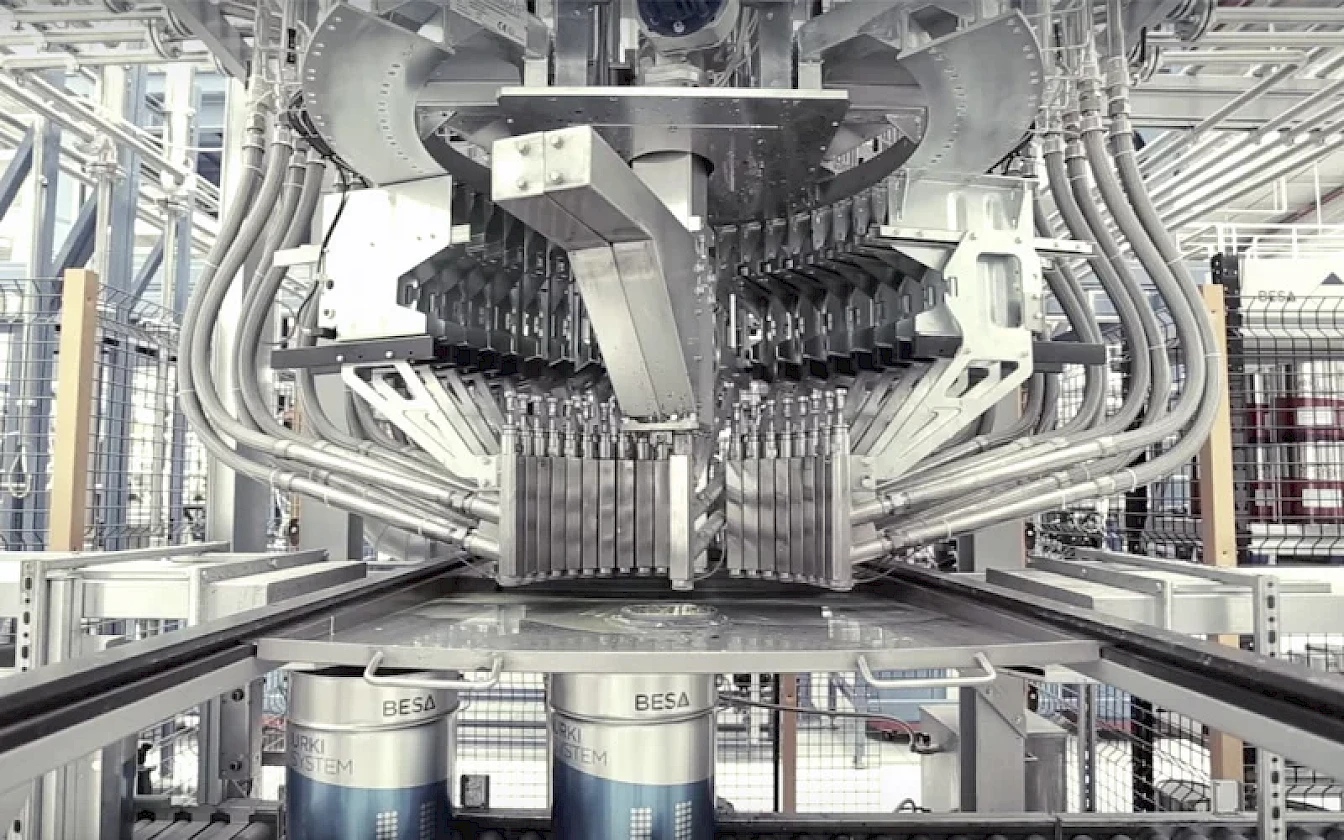

Technically, we can say that industrial paint is a product that, presented in liquid, paste or powder form, and applied by a suitable process to a surface, shall be transformed by a curing process into a solid, plastic, adhesive film that protects and/or decorates simultaneously.

Focusing on the industrial field, we can define as industrial coating the products involved in the painting, conservation and maintenance processes of structures, machinery, consumer goods and any product associated with a certain industrial sector.

Purpose of industrial paint

Industrial paint has two main objectives:

On the one hand, to protect the different supportsfrom the aggressions they may be subjected to, both physically (impacts) and chemically and environmentally (corrosion, weather, etc.).

On the other hand, to give the part a better aesthetic appearancein order to obtain an optimal finish, even increasing its added value.

This last point being somewhat more subjective and difficult to assess, we will focus on the information of a painting system that guarantees an excellent performance depending on the medium it will be exposed to.

Elements that make up industrial paint

Pigments

Its purpose consists primarily in giving colour and opacity to the paint coat. These are generally solid substances in the form of very fine particle size powder which, through a suitable milling process in the presence of the binder, are broken down into elementary particles to obtain the maximum colour performance.

The different pigments can be classified as:

Covering pigments are the most widely used. They confer opacity to the paint through the combined effect of its refractive index in relation to the binder, granulometry and phenomena of reflection of the light that falls on the paint coat.

Anti-corrosion pigments: used in the primers or first coats of direct contact with the steel, prevent and inhibit corrosion by anodic or cathodic passivation of the electrochemical current produced on the metal surface.

Spreading pigments or fillers have no opacity and hardly influence the colour of paints because of their low refractive index. They are generally used in primers and base coats to achieve matte or satin films and as filler in the paint coat. Examples: calcium carbonate, talc, mica, kaolin, etc.

Special Pigments: some of the pigments used in industrial coatings that cannot be classified in the above categories because of their specificity include:

- Metal pigments.

- Pearlescent pigments.

- Intumescent pigments.

- Toxic pigments.

Binders

It is the basic component of the paint which gives it the possibility of forming an adherent film after the paint has dried. The mechanical and chemical features of the paint depend on the binders, and therefore on their protective capacity.

Technically they are polymers with low or medium molecular weight, which through the action of oxygen in the air, heat, etc., increase their level of polymerisation until they become more or less plastic and insoluble solids. Here are some examples of binders:

- Alkyd resins.

- Acrylic resins.

- Vinyl resins.

- Epoxy resins.

- Polyester resins.

- Polyurethane resins.

- Cellulose resins

- Chlorinated rubber resins.

- Etc.

Solvents

The mission of the solvents basically consists in allowing the paint to be applied though the chosen procedure, giving it an appropriate consistency, since a solvent-free paint, only based on pigment and binder, would generally have a very high viscosity.

Another of its missions is to enable the manufacture of the paint and maintain its stability in the container.

Usually several types of solvents are used in the same paint in order to regulate the dissolving power, ease of application, levelling, etc. For example: aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, chlorides, ketones, etc.

Additives

They are specific action chemicals that are added in small proportions to the main components of the paint for different purposes such as improving product quality, producing special effects, accelerating hardening, conferring thixotropy, tinting, etc.

Examples of paint additives: wetting agents, thickeners, dulling agents, drying agents, fungicides, plasticisers, etc.