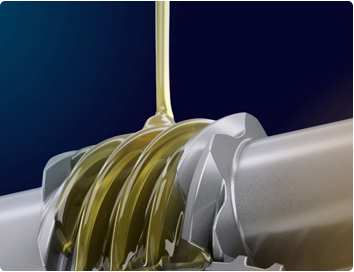

Hydrotreated Base Oils that typically have high purity levels

Group II Base Oils Overview

Group II base oils are an improvement over Group I oils, offering enhanced purity and performance. They are produced using hydrocracking and hydroprocessing techniques, which result in oils with a higher degree of refinement and stability.

Key Characteristics

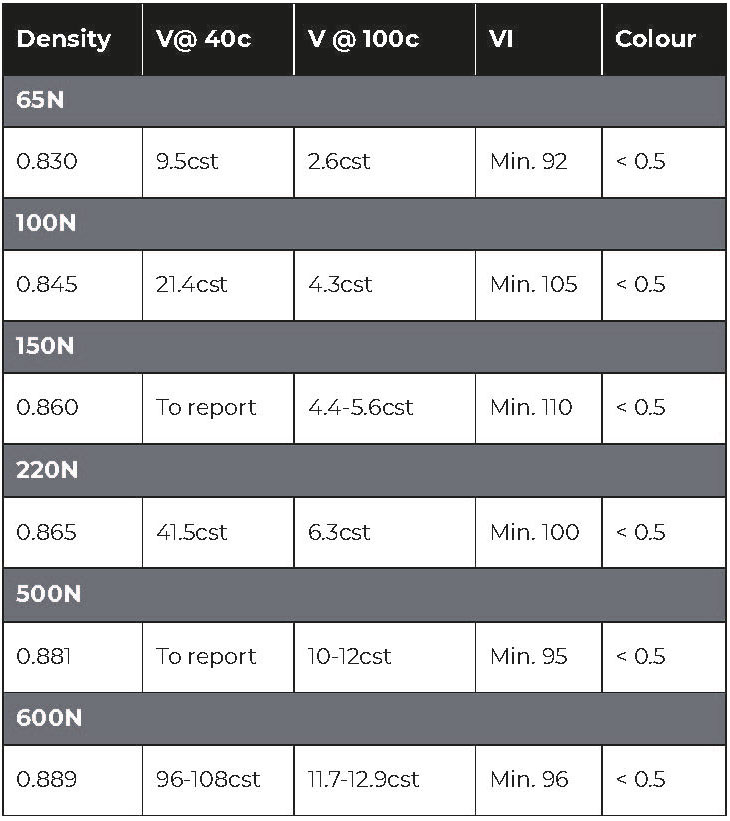

-

Chemical Composition:

- Saturates Content: Greater than 90%.

- Sulfur Content: Less than 0.03%.

- Viscosity Index (VI): Between 80 and 120, similar to Group I.

-

Physical Properties:

- Clearer in color compared to Group I.

- Better oxidation stability due to reduced impurities.

-

Production Process:

- Made through hydroprocessing, which removes sulfur and other impurities and saturates aromatic compounds.

- The process uses high pressures, hydrogen, and catalysts to improve the molecular structure and remove undesirable elements.

Advantages

- Enhanced Oxidation Stability:

- Reduces sludge formation and extends lubricant life.

- Cost-Effective:

- Offers better performance than Group I without the high costs of Group III or synthetic oils.

- Wide Range of Applications:

- Suitable for a variety of industrial and automotive uses.

Disadvantages

- Moderate Performance:

- Not as high-performing as Group III or synthetic oils in extreme environments.

- Additive Compatibility:

- May require additional additive packages for specific applications.

Applications

- Automotive Lubricants:

- Engine oils, transmission fluids, and gear oils.

- Industrial Lubricants:

- Hydraulic fluids, compressor oils, and turbine oils.

- Process Oils:

- Used in manufacturing and blending processes where moderate performance is sufficient.

Comparison with Group I and III

- Group I: Group II has better oxidation resistance, lower sulfur content, and a clearer appearance.

- Group III: Group III offers a higher viscosity index and is more suitable for extreme temperature ranges but is more expensive.

For further information and detailed specifications, please contact us.

Please note: Colour of base oil will vary according to source and refinery process.